阅读次数: 次 发布日期:2020-05-21

无锡航一机械有限公司 WUXI HY MACHINERY CO., LTD.

Belt-feeding type Packing Machine, lamb Feed packing machine, fish feed bagging machine, pig Feed packing machine, livestock Feed packing machine, Feedmill packing machine, feed mills bagging machine, Soybean Meal bagging machine, Corn packing machine, DDGS Corn bagging machine, Wheat bagging machine, Stone Kernels bagging machine, Bone Flour bagging machine, packing machine Canola Meal bagging machine, Premix bagging machine, Birdseed bagging machine, packing machine horse Feeds bagging machine, Meals and Stock Feeds bagging machine, Poultry Feeds bagging machine, Whole Grains packing machine, Cracked Grains bagging machine, Food and Ingredients bagging machine packing machine

Application

With the belt-feed weighers, the belt feeding bagging machine's weighing container is filled by conveying the product using a belt conveyor. The belt-feed system is ideal for medium-flowing floury products, pellets, granules and flakes. It's widely used for weighing packing animal feed, tablets, particles with powder, wood pellets, sand and gravels, aggregates, aluminium sulphate, perlite, building materials, calf meal, livestock feed, coal, mixture, tea, fertilizers, compost, Peat Moss, chemical materials and other tablets, pellets, etc.

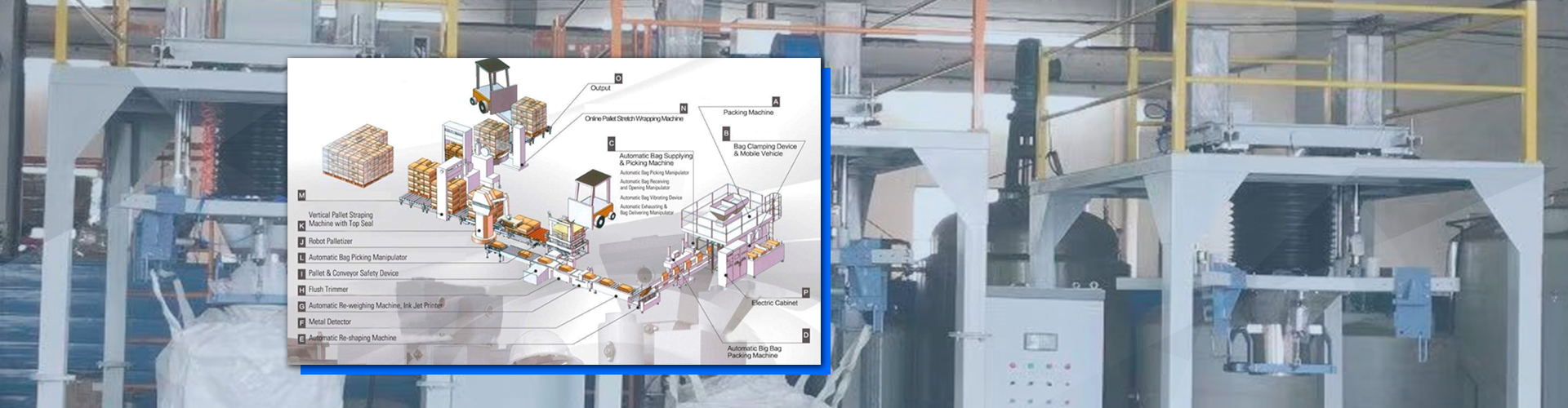

It's optional to install loading conveyors, dust collector, sewing machine, heat sealing machine, weight checker, metal detector, coding machine, robot palletizer, high-level palletizer, pallet wrapping machine, etc. to make the complete production line. Produced by Wuxi HY Machinery Co., Ltd.

Technical Parameter

Model: LCS-HYB series

Weighting Range: 1~100kg, customized

Accuracy: within 0.2%

Capacity: 180-220bags/hour, 300-360bags/hour, 500-700bags/hour, 700-900bags/hour

Power Supply: AC110-240V/220-600V, 50/60Hz, 1/3P, customized made as per local electrical system

Power: 2.8~5.5 kW, depends on packing speed capacity.

Air Resource: 0.4~0.6 Mpa ( 0.2m3/min air consumption)

Bag Belt Conveyor Dimension: 3000*400mm, customized design.

Working Process

Manually bag placing → Automatic filling → Automatic weighing → Automatic conveying → Automatic sealing (sewing, heating or welding) → next process

Feature

Your benefits due to our experience:

1) Clean bag filling

Due to product-specially chosen filling spout with all-side clamping jaws

2) Space saving

Due to compact machine design

3) Cost saving

Due to stable operation and low maintenance costs

4) Easy handling

Due to easy and intuitive operational menu with weight input;weight display; time display;

Due to clear operator guidance, easy cleaning and maintenance

5) High weight accuracy: 0.2%FS

Due to coarse and fine flow filling speed

Due to the use of the Touch screen or METTLER TOLEDO weighing controller and high reliable load cell sensors

6) Good product protection

Due to project-specially selected bag closure, e.g. sewing, welding or hot-melt sealing

Service

1. Project analysis

According to your product specifications and packing requirements, in order to guarantee the packing speed and accuracy, we will analyse your products and your bags after receipt of your inquiry to select the right filling technology for your project in close cooperation with you. And our solution will be the perfect combination of product, packing material and machine.

Product analysis:

- Mesh size

- Corrosivity

- Bulk density

- Flowability

- Humidity

- Feeding methods

Our practice-orientated tests lead to economic packaging solutions, customized design for your individual needs, and facilitate the collection of process-relevant product data. So you can be assured that your products will fulfill your customers in the desired quality day after day.

2. Technical customer service

Our service does not end with the delivery of your new packaging plant. We offer a wide range of after-sales services, e.g. commissioning of your machine or later regular maintenance of your packaging plant.

A team of well-trained service technicians is at your disposal. They all have extensive experience with packaging technologies in combination with different products and bags all over the world.

Contact us by kingmoon0523@hotmail.com We Wuxi HY Machinery Co., Ltd. will be pleased to support you at any time.

3. Spare parts

Lifetimes of machines are largely influenced by the quality of the used components. Thanks to an extensive stock of spare parts we are able to supply original spare parts fast at short notice.

You profit from using original parts: Optimally fitting into the machines they guarantee highest outputs and lifetimes.

4. Safety engineering

The safety of our supplied machines and plants is one of our top priorities. Thus, part of our essential goals is to best help you avoid damage caused by machines and ensure maximum safety for your personnel. In addition, there is a large number of safety guidelines regulated by law that have to be considered when constructing machines. We support you in developing the right safety concept for your packaging project, produced by Wuxi HY Machinery Co., Ltd.