阅读次数: 次 发布日期:2020-05-21

无锡航一机械有限公司 WUXI HY MACHINERY CO., LTD.

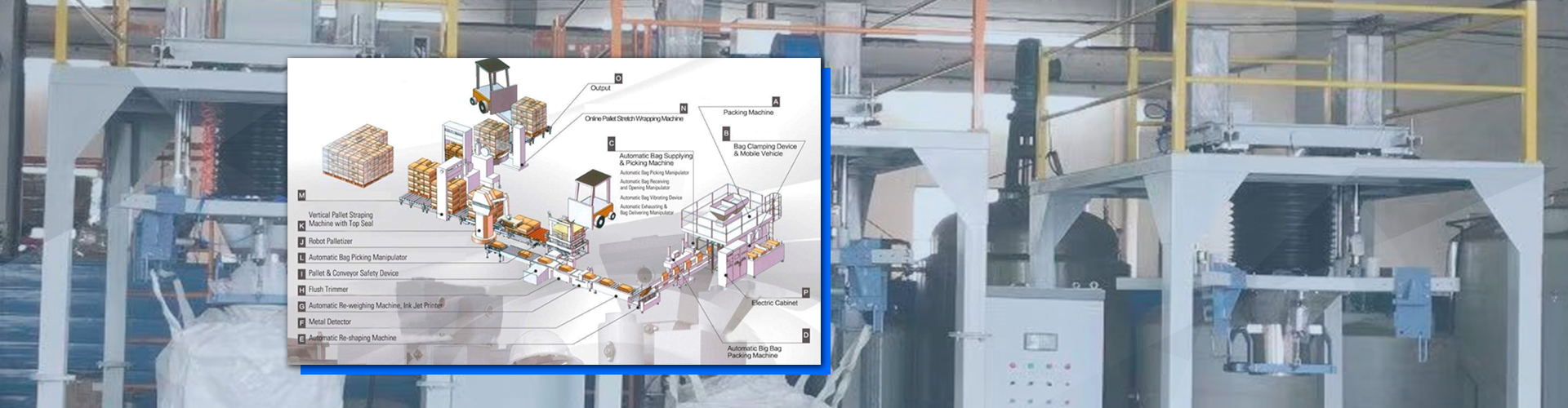

Robot palletizer, palletizing machine

Description

Robot palletizer adopts advanced palletizing robot for stacking. Simple structure, small covering space, simple operation, low power consumption and easy maintenance. Using touch-screen operation.

Robot palletizer is widely used in the packaging machinery industry. The latest robot palletizing machine has the features of simple structure, small size, light weight, faster speed, more safety, energy-saving, good looking, less power, etc. And it can significantly shorten the length of the production line, reduce the amount of equipment and simplify the work procedures. Through setting, the robot will be able to complete the task of discharging and palletizing nylon (paper) bags, plastic bag, cardboard box, plastic containers, glass bottles, etc.

It’s optional to install automated bagging machine, packing machine loading conveyors, dust collector, sewing machine, heat sealing machine, weight checker, metal detector, coding machine, pallet wrapping machine, etc. to make the complete production line. Produced by Wuxi HY Machinery Co., Ltd.

Technical Parameter

Model: ABB / Kawasaki / Estun

Grasping scope: 10-50kg bag, customized as per requirement

Palletizing capacity: customized, matching with the automatic packing machine line.

The mechanical structure: Multi-joint robot

Action mode: cylindrical coordinate type

Grasping hand: finger type

Stacking memory capacity: standard 30 kinds (up to 400 kinds)

Stack height: max.2300mm

Stack width: max.1500mm

Control Method : PLC

Square area: L 2000mm×W4000mm

Stack type structure: customized

Stack form: According to the user’s needs, single/double station

Service

1. Project analysis

According to your product specifications and packing requirements, in order to guarantee the packing speed and accuracy, we will analyse your products and your bags after receipt of your inquiry to select the right filling technology for your project in close cooperation with you. And our solution will be the perfect combination of product, packing material and machine.

Product analysis:

· Mesh size

· Corrosivity

· Bulk density

· Flowability

· Humidity

· Feeding methods

Our practice-orientated tests lead to economic packaging solutions, customized design for your individual needs, and facilitate the collection of process-relevant product data. So you can be assured that your products will fulfill your customers in the desired quality day after day.

2. Technical customer service

Our service does not end with the delivery of your new packaging plant. We offer a wide range of after-sales services, e.g. commissioning of your machine or later regular maintenance of your packaging plant.

A team of well-trained service technicians is at your disposal. They all have extensive experience with packaging technologies in combination with different products and bags all over the world.

Contact us by kingmoon0523@hotmail.com We Wuxi HY Machinery Co., Ltd. will be pleased to support you at any time.

3. Spare parts

Lifetimes of machines are largely influenced by the quality of the used components. Thanks to an extensive stock of spare parts we are able to supply original spare parts fast at short notice.

You profit from using original parts: Optimally fitting into the machines they guarantee highest outputs and lifetimes.

4. Safety engineering

The safety of our supplied machines and plants is one of our top priorities. Thus, part of our essential goals is to best help you avoid damage caused by machines and ensure maximum safety for your personnel. In addition, there is a large number of safety guidelines regulated by law that have to be considered when constructing machines. We support you in developing the right safety concept for your packaging project, produced by Wuxi HY Machinery Co., Ltd.