阅读次数: 次 发布日期:2020-05-21

无锡航一机械有限公司 WUXI HY MACHINERY CO., LTD.

Valve Bag Filling Machine, Fully Automatic Valve Bag Packing Line, Kraft Paper bag filler, Valve bags packer, Valve Bag Weighing Bagging Machine, Vacuum Type Valve Bag Filling Machine

1) Valve Bag Filling Machine

Application

This is valve type filling machine, kraft bag filling machine for filling materials into valve bag. It's suitable for filling It’s suitable for filling Cement, refractory powder, flour, building materials, dry mortar, readymix, plastic pellets, masterbatches, carbon black, PVC, fine powder, fumed silica, precipitated silica and alumina, fine graphite powder, Calcium Phosphate Tribasic;Bone Flour; Bone phosphate; Calcium orthophosphate; Calcium Phosphate; Calcium phosphate (3:2); Calcium tertiary phosphate; Phosphoric acid,calcium salt (2:3); Phosphoric acid, calcium(2+) salt (2:3); Tertiary calcium phosphate; Tribasic calcium phosphate (Ca3(PO4)2); Tricalcium orthophosphate; Tricalcium Phosphate; Tricalcium diphosphate; APATITE TTCP, MONOCLINIC; bonarka; calcigenolsimple; calciumorthophosphate,tri-(tert); calciumphosphate(3:2); calciumphosphate(ca3(po4)2); calciumtertiaryphosphate; naturalwhitlockite; (Tricalcium phosphate); Calcium phosphate, tribasic; tricalcium phosphate activated; extra-fine calcium phosphate; superfine calcium phosphate; calcium hydroxide phosphate (5:1:3); calcium hydrogen phosphate, etc. Produced by Wuxi HY Machinery Co., Ltd.

Main Features:

1. Automatically measurement by computer, automatic feeding-in, continuously operation, accurate data;

2. Using high-speed processing instruments and sampling frequency digital technology which can suit for different materials, easy to operate;

3. Rational structure, small space, flexible installation and maintenance simple;

4. Dynamic display, parameter storage, automatically saved data, balance pressure system, multi-function display and fault monitoring, automatic diagnostic techniques, multi-data communications interface, Standard communications interfaces, which used to print statements,easy-site management and centralized control of management;

5. The main components are imported with high-grade.

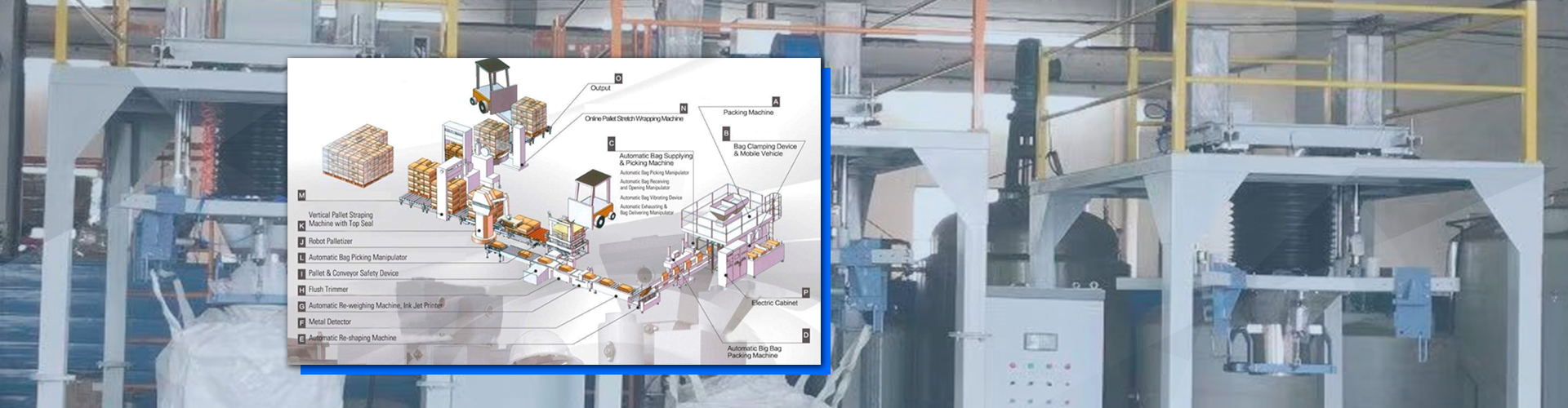

It's optional to install loading conveyors, dust collector, sewing machine, heat sealing machine, weight checker, metal detector, coding machine, robot palletizer, high-level palletizer, pallet wrapping machine, etc. to make the complete production line. Produced by Wuxi HY Machinery Co., Ltd.

Technical Parameter

Model: LCS-HYF series ( screw type, impeller type, air type, multi type, etc.)

Weighting Range: 1~100kg, customized

Accuracy: +/-0.2~1%

Capacity: 180-220bags/hour, 300-360bags/hour, 500-700bags/hour, 700-900bags/hour

Power Supply: AC110-240V/220-600V, 50/60Hz, 1/3P, customized made as per local electrical system

Power: 2.2~7.5 kW, depends on materials features.

Air Resource: 0.4~0.6 Mpa ( 0.2m3/min air consumption)

2) Fully Automatic Valve Bag Packing Machine (LCS-HYFQ)

Applications:

As per your needs of fully automatic valve bag filling machine with automatic valve bag placer for cement 25-50kg valve bags, we advise you this LCS-HYFQ model fully automatic valve bag filling machine very suitable for weighing filling the materials into valve bags. Fully Automatic Valve Bag Packing Line Produced by Wuxi HY Machinery Co., Ltd.

I. Brief Introduction

This automatic packing machine is controlled by PLC program. Firstly, conveying an empty bag into the bag bucket from the bag warehouse and then the bag bucket will rise and then bag arm lifts and extending its sucker hand to suck the bag. The bag mouth will be opened by the hand when bag arm returns to insert the bag onto filling nozzle. Then the weighing filling part starts to work, and after the bag is filled to the set weight, it will be pushed down to the belt conveyor for next round.

II. Main Parts and Function

Part 1. Empty Bag Feeding System

Ø Before start the machine, manually place 50-100 pcs of bags in front of the forks.

Ø Each stack: 50-100pcs

Bags must be properly stacked in order to run smoothly

Part 2. Automatic Bag Placer

Ø Vacuum sucking technology

Ø Automatic open the bag mouth

Ø Precise Positioning

Ø Non bag dropping due to advanced structure design and technology

Part 3. Weighing Filling System

Ø Different feeding methods, such as pneumatic feeding, screw feeding, impeller feeding,etc. according to different packing materials and requirements;

Ø High filling accuracy due to advanced weighing sensor and indicator Brand F701/ Mettler Toledo/General Measure;

Ø Machine material: Product contact surface is made of Stainless steel 304, other parts are carbon steel;

Ø Option: Dust removal access, to ensure clean working environment

Part 4. Bag Pusher and Conveyor

Ø After finishing filling, the bag will be pushed out of the nozzle automatically and drop down the conveyor.

It’s optional to install loading conveyors, dust collector, sewing machine, heat sealing machine, weight checker, metal detector, coding machine, robot palletizer, high-level palletizer, pallet wrapping machine, etc. to make the complete production line. Produced by Wuxi HY Machinery Co., Ltd.

3) Superfine Powder Vacuum Type Valve Bag Packing Machine

Application

LCS-HYZF1550 model Superfine Powder Vacuum Type Valve Bag Filling Packing Machine is a closed system consists of the feeding mechanism, filtration transport unit, sealed conversion parts and other components. And it’s also suitable for 200 mesh to 8000 mesh super fine powders.

Its principle:Adopt the pressure difference between the feeding mechanism and the vacuum chamber, in vacuum state, it would feed the packaging process of extremely light and/or extremely fine powders into the bag from raw materials warehouse. It completely solves the extremely light and fine powder’s packaging problem of difficult packaging, bulky, and serious pollution problem.

Operating system: human design, PLC program combined control, designed according to the physical properties of materials, packaging specifications and packaging speed. Continuously feedback through signal positive and negative communication. With PLC, it’s finishing the automatic control of the production process, the negative pressure level and the feeding speed. Ensure to compliance with the customer's different packaging requirements due to raw materials different density and different speeds, and thus to meet customers specific demands of weighing packaging solution.

Production process: full automatic operation, with features of fast packaging speed, high accuracy and no dust pollution.

Mainly application: Feeding and filling the very light, extremely fine nano powders (such as fluffy carbon black, fumed silica, precipitated silica and alumina, titanium, and fine graphite powder, etc.) into the valve bag. It’s widely used powder production plant or powder re-packing factory and others.

Service

1. Project analysis

According to your product specifications and packing requirements, in order to guarantee the packing speed and accuracy, we will analyse your products and your bags after receipt of your inquiry to select the right filling technology for your project in close cooperation with you. And our solution will be the perfect combination of product, packing material and machine.

Product analysis:

-Mesh size

-Corrosivity

-Bulk density

-Flowability

-Humidity

-Feeding methods

Our practice-orientated tests lead to economic packaging solutions, customized design for your individual needs, and facilitate the collection of process-relevant product data. So you can be assured that your products will fulfill your customers in the desired quality day after day.

2. Technical customer service

Our service does not end with the delivery of your new packaging plant. We offer a wide range of after-sales services, e.g. commissioning of your machine or later regular maintenance of your packaging plant.

A team of well-trained service technicians is at your disposal. They all have extensive experience with packaging technologies in combination with different products and bags all over the world.

Contact us by kingmoon0523@hotmail.com We Wuxi HY Machinery Co., Ltd. will be pleased to support you at any time.

3. Spare parts

Lifetimes of machines are largely influenced by the quality of the used components. Thanks to an extensive stock of spare parts we are able to supply original spare parts fast at short notice.

You profit from using original parts: Optimally fitting into the machines they guarantee highest outputs and lifetimes.

4. Safety engineering

The safety of our supplied machines and plants is one of our top priorities. Thus, part of our essential goals is to best help you avoid damage caused by machines and ensure maximum safety for your personnel. In addition, there is a large number of safety guidelines regulated by law that have to be considered when constructing machines. We support you in developing the right safety concept for your packaging project, produced by Wuxi HY Machinery Co., Ltd.